Reference Project – Energy Offshore

Special Expertise – Ice Technology / Shallow Water Technology

Kashagan Field Development – Kazakhstan

Project Facts

Client

Shell Kazakhstan, OKIOC, Agip-KCO, Mallard Bay Drilling, Rig Design Services

Project Location

North Caspian Sea, Kazakhstan

IMPaC’s Services

65,000 hours

Investment

700 million USD (related to IMPaC’s scope of work)

Year

07/1997 – 11/2009

IMPaC’s Scope

FEED study for Cantilever Barge Rig

Feasibility Study for the first North Caspian Drilling Rig

Detail design and construction supervision of ice resistant sponsons for Parker Rig 257, SUNKAR

Detail design, procedure, supervision and evaluation of full-scale sliding resistance test results

Construction supervision and offshore installation supervision of Rig 257, SUNKAR

Conceptual design and cost estimate of various types of drilling platforms

Detail design and installation supervision of ice protection piles

Specification and supervision of ice model tests carried out at HSVA-Hamburg

Detail design incl. wave model tests of drilling rig support barges

Project Characteristics

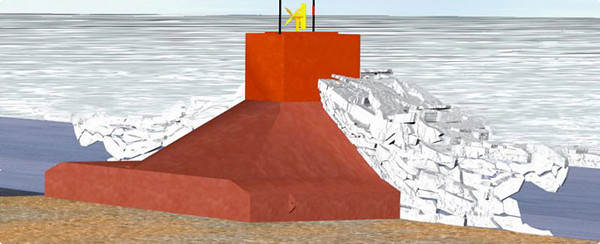

The Kashagan oil field is located in very shallow water (2 m to 8m) with high reservoir pressure and large quantities of H2S. Loads due to drifting sea ice during winter drilling operation posed an additional risk.

As specialists for ice engineering and shallow water technology IMPaC has been assigned for facilities design from concept to detail for Kashagan field development. The project started with the conceptual study for base of drilling facilities incl. jackets, artificial islands and barge concept followed by screening and prequalification exercise of local shipyards.

For conversion of a former exploration swamp barge Rig 71 to ice resistant drilling barge SUNKAR, Rig 257 IMPaC prepared overall stability and detailed design and provided construction supervision services of the entire rig. In this harsh environment of the North Caspian Sea accurate ice protection of SUNKAR by ice resistant piles has been required. Furthermore conceptual, basic, detailed design and construction supervision were provided for different facilities incl.

- ice resistant wellhead protector

- Living quarter barges

- Lighter barge for SUNKAR drilling rig

- Emergency Escape & Rescue barges (EER)

IMPaC also has been assigned for FEED services for a purpose-designed cantilever barge rig for drilling in grounded condition incl. marine system.